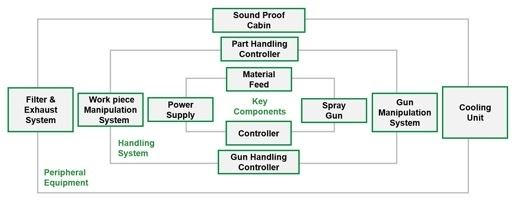

Over the years, EP Coatings has designed, produced, and installed countless state-of-the-art turn-key finishing systems for projects spanning a variety of industries worldwide. Such coating systems generally include the core thermal spray technology and management systems, as well as all of the necessary outlying components like dust collectors, robotic handling, soundproof spray booths, and turntables. These components can be fully automated, giving users more freedom to monitor and control the operation in a way that’s convenient to them.

How we can help with turn-key thermal coating systems

Call our friendly team if you’d like to learn how we can help you see a custom turn-key coating project through from start to finish, handling:

- Engineering and design

- Factory acceptance testing (FAT)

- Installation

- Maintenance/Support

- Project management

- Site acceptance testing (SAT)

- Technical kick-off meeting

- Thermal spray equipment manufacturing

- Training/Qualifications

Thermal Spray Process Support

You’ll never be left wanting with EP Coatings (EPC), as we supply a complete range of thermal spray coating systems to meet every individual need during the coating process. Our stand-alone units can help immensely with a wide range of processes like plasma spraying, HVOF, powder spraying, wire flame spraying, and electric arc spraying. Furthermore, we can supply you with innovative multi-process coating systems that effortlessly cope with several processes using only one controller. For example, our state-of-the-art MP-50 Digital Series not only handles multiple processes with ease, it can also control other outlying systems.

At EPC, we have an in-depth knowledge and experience with thermal spraying processes and coating systems, and we will happily share this expertise with you as part of your turn-key project. This means you can benefit from specific application know-how, parameter and component development, process optimization, robot programming, and much more. This knowledge enables you to begin production as soon as possible, without the hassle of having to navigate a steep learning curve. So, if you need a knowledgeable and reliable partner for your turn-key thermal spray project, look no further than EPC.

Offering You Safety & Quality

EPC always prioritizes safety and quality when designing, manufacturing and installing our coating systems. Our smart thermal spraying systems and innovative software design combined with premium integrated sensors and e-stops ensure that all operations are carried out safely and to a high standard. Once all of your thermal spray equipment has been professionally installed, our skilled and friendly team will happily train you on how to properly operate your new coating systems, as well as how to maintain it. They will also answer any questions you have about thermal spray technology, putting your mind at ease as you carry out your project.

Auxiliary Equipment for Turn-Key Coating Projects

EPC really is a one-stop-shop when it comes to meeting your thermal spraying requirements, offering a comprehensive, continuously expanding line of auxiliary thermal spray equipment in addition to the installation of main systems and sharing of technical expertise. These supporting products can be purchased as part of turn-key coating solutions or as stand-alone units, and they are all specifically designed to work in harsh thermal spraying environments. Our equipment range includes:

• Acoustical spray booths

- We can provide fully customizable modular booths that are sound-absorbent and suitable for your thermal spraying needs.

• Chiller/cooling systems

- EPC offer a range of efficient cooling units that are designed to offer maximum performance (30-200k capacity) at a minimum amount of floor space.

• Dust extraction and collection systems

- EPC uses the Camfill/Farr GX-series dry cartridge dust collector to filter and collect dust, and to effectively remove heat generated by thermal spraying processes.

• Gun and part manipulation equipment

- Our gun and part manipulation equipment precisely controls the movement of the workpiece and the relative position to the spray torch, helping you achieve a consistent coating.

• Mounting fixtures

- We stock a variety of gun mounting fixtures suitable for both robot and/or spray lathe systems.

- All of our torch fixtures are engineered to eliminate interference by isolating the thermal spray torch from the manipulation system.

• Part cooling systems

- We offer a range of high-quality part cooling systems including air distribution units, cooling stands, gun air jets and manual air guns.

• Powder feeders

- EPC offer powder feeders that are designed for all powder based thermal spray processes. Our Feeders have excellent track records in providing high precision and repeatable powder feed for both thermal spray and laser cladding processes.

• Tecnar Accuraspray 4.0

- Tecnar Accuraspray 4.0 allows you to effortlessly monitor your thermal spraying processes to ensure spray conditions are optimal for ideal coating performance. This leads to more consistent coatings and increased productivity.

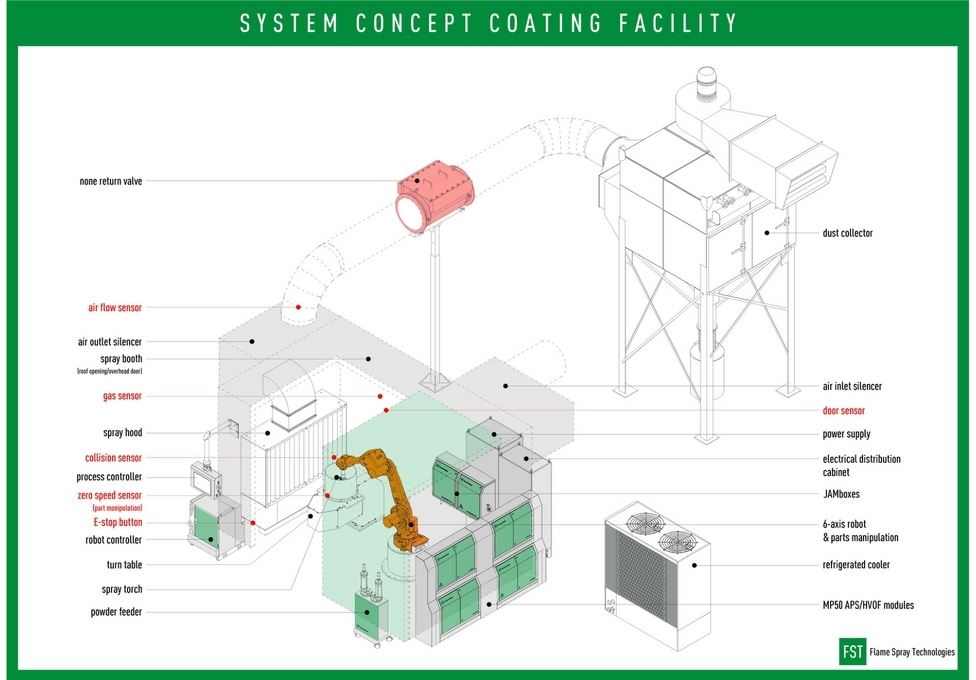

Turn-Key System Concept Coating Facility

Images courtesy of FST

Airflow sensor: a safety feature that ensures the dust extraction flow is active during the process, so the process can be started and shut down safely.

Air outlet silencer: each outlet silencer is designed for optimal flow throughout, and minimizes the noise outside the spray booth to acceptable levels.

Collision sensor: these robotic collision sensors automatically detect when the robot arm has encountered an obstruction, then they act fast to absorb the crash energy and prevent the robot arm, thermal spray torch, and spray object from being damaged.

Dust collector: proper airflow during the thermal spray process is essential in order to meet worldwide operator safety and environmental regulations. According to the Thermal Spray Booth Design Guidelines prepared by the ASM-TSS Safety Committee, an effective exhaust system is vital because:

- proper airflow throughout the spray booth prevents the build-up of potentially dangerous gases, fumes, reaction by-products, and dust particles, allowing the thermal spraying process to be carried out safely.

- thermal spray processes produce heat, meaning that without proper ventilation the temperature inside the booth will rise to unsafe levels.

- poor ventilation can have adverse effects on coating quality.

- the effluents that aren’t consumed by the thermal spray processes or deposited must be removed from the environment. This safeguards the thermal spray equipment and protect the operator from potential hazards.

Door sensor/door interlock: these access door interlocks are safety switches that ensure the booth doors are fully closed before the thermal spraying process begins, and they also stop the process if the doors are opened during the process.

E-stop: the easily accessible e-stop button(s) are used in an emergency to try to limit or avert harm to someone or something. Activating one of the e-stop buttons immediately causes a complete stop for both thermal spray process and robotic movements.

Electrical distribution cabinet: Our turn-key thermal spray solutions come with a handy electrical distribution cabinet (EDC) that houses all electrical connections for each system subcomponent and all circuit breakers. With our EDCs, consumers only need one main electric connection to perform operations.

Gas sensor: this blocks gas flow under certain conditions and detects ventilation problems. in addition to problems with lack of ventilation.

Jamboxes: a jambox cabinet is usually mounted inside the booth for each thermal spray process:

- Gasses and power for the APS process (AP-50) are distributed to this jambox.

- Liquid or gas fuels are distributed for the HVOF process (HV-50).

- The spray torch hoses and cables are connected to the jambox.

- For multi-process (MP-50) operations, a water switch module is built into the HV-50 jambox.

- The AP-50 Jambox also contains a high-voltage discharge unit for APS torch ignition and a water flow meter for accurate spray torch cooling.

Non-return valve: the ATEX non-return valve is there so that if a deflagration (explosion) occurs in the dust collector, it won’t travel back down the inlet pipe into the spray booth.

Powder feeder: these powder feeders can be used with all powder-based thermal spray processes (including plasma and HVOF).

Power supply: we provide a reliable power supply unit for the operation of different plasma torches during the APS thermal spray process.

Process controller: EP Coating’s Horizon operating software is controlled from this 22’’ human machine interface (HMI) touchscreen that can be ergonomically mounted on a wall or tool post.

Refrigerated cooler: high-end thermal spraying methods such as HVOF and plasma processes require reliable and accurate water-cooling systems to maintain spray torch stability and effectiveness. EPC refrigerated coolers allow you to adjust the water temperature accurately to within a few degrees, and a deionizer is built into the water chiller to minimize corrosion in the gun and control conductivity during the APS process.

Robot controller: control centrum of the robot handling equipment.

Robot & part manipulation: all of EPC’ systems are carefully engineered, taking into account the shape, weight and quantity of the soon-to-be-sprayed components. We custom design a range of components handling systems to suit every application, and all of our spraying equipment is integrated into the turn-key service to a level that fits the application requirements. In most cases, the robotic manipulation equipment controls all other components of the total turn-key solution, allowing for optimal process control and high-quality coating consistency.

Spray booth: a thermal spray booth is an enclosed structure that works with other subsystems (including interlocks, controls, and ventilation/filtration) to provide effective control and protection from the hazards associated with the thermal spray process, including:

- Excessive sound levels

- Powder/dust from the process

- Gases/fumes

- Visible light and ultraviolet (UV) radiation

Spray torch: We offer multiple torch technology that can handle most thermal spray torches, including:

- cGun, F4, F100, 3/7/9MB (MBT), SG-100, and I.D. plasma torches.

- eGun, JP-5000 and diamond jet and most other available HVOF process torches.

Turntable: the turntable is a combined and integrated or stand-alone controlled component manipulation system designed for automatic, replicable coating applications for the specified components.

Zero speed sensor: this component can tell if the turntable or spray lathe unexpectedly stop moving, and then the spray process automatically shuts down. This stops parts from being damaged and prevents potentially hazardous situations.

50 Digital Series: EPC offer a 50 digital series system is a thermal spray system using advanced mass flow controllers for process gasses and carrier gasses. The system boasts various safety features and closed-loop control of all important process components based on Siemens 1500PLC technology. The MP-50 is modularly designed and works with separate gas modules and jamboxes for each of the processes. This combined with the control system significantly enhances the safety, stability, and reliability of the entire system. What’s more, the touchscreen interface with our innovative Horizon operation software is incredibly intuitive and easy to use.

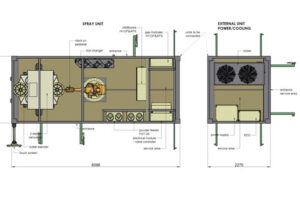

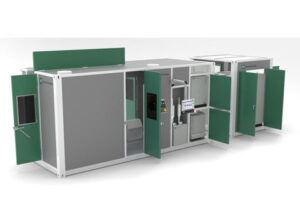

The Coating Machine™

The Coating Machine™ is a ready-to-use flame spray production unit specifically designed to suit a wide variety of industries. The machine is operated using EP Coatings’ advanced Digital 50 Series process controllers and provides many benefits, such as:

• Convenience

- Equipment is pre-installed and commissioned

- The system is shipped as a fully operational ‘plug and play’ spray facility ready for production to begin

• Flexibility

- Comes with a range of options to suit every need

• Quality

- The Coating Machine™ is robustly built to the highest standard using high-quality components

• Reduced costs for customers

- Each operating unit is standardized and automated

The Coating Machine™ is fully compatible with all conventional coating processes including APS, HVOF, Flame Wire, Flame Powder, and Arc Spray, and it comes in three different configurations:

1. The Coating Machine™ Type I

- a. ABB IRB 4600 45/2.05 robot, T1200 non-tilting turntable (1,200kg max. load)

- b. ABB IRB 4600 45/2.05 robot, LTT1200 tilting turntable (1,200kg max. load)

2. The Coating Machine™ Type II

- a. ABB IRB 4600 45/2.05, 2 station carousel (100kg max. load)

- b. ABB IRB 4600 45/2.05, 8 station carousel (25kg max. load)

3. The Coating Machine™ Type III

- a. ABB IRB 4600 40/2.55, L3500 spray lathe, 2,500mm between centers (1,000kg max. load)

- b. ABB IRB 4600 40/2.55, L2500 spray lathe & turntable (lathe: 1,000kg and turntable 300kg max. load)